For Part 2, Go HERE

For Part 3, Go HERE

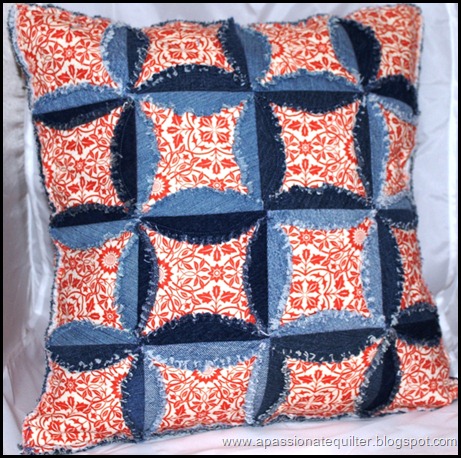

Here are the supplies you will need:

1. Sixteen- 6 ½” denim circles (*1-2 pair of 100% cotton jeans)

*1 pair will make 12-16 circles depending on the jean size

2. Sixteen- 4” batting squares (I use a thin, 100% cotton batt)

3. Sixteen- 5” charm squares

4. Thread to match jeans

5. Spring loaded scissors for clipping seams

6. Stiff brush (i.e. cleaning brush)

7. Pillow form- 18”

8. ½ yard fabric for pillow backing

9. Spray Starch

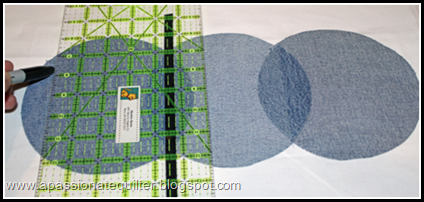

1. CUT sixteen (16) - 6 1/2” Denim Circles

**If you want a variety of blues in your pillow, you will need to cut circles from several different blue jeans.

It’s important to use 100% cotton or close to it (97%, 99%). I have a lot of trouble getting the stretch jeans to fray!

Remove both legs from one pair of jeans. I like to cut just underneath the pockets for maximum usable yardage.

Next, cut open each leg at one seam. Open the leg and iron flat.

You now have two usable pieces of fabric from one pair of jeans.

Cutting the Denim Circles?

Options…

1. Trace around a 6 1/2” circle template and cut out with scissors

or a rotary cutter.

2. Use an OLFA circle cutter.

*This is my preferred method.

****BIG TIP!

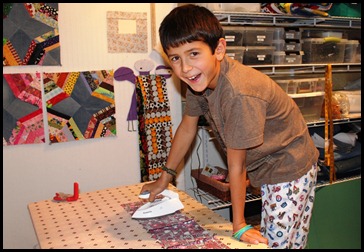

-Heavily spray starch your jeans just prior to cutting, especially, if you are using the OLFA circle cutter. This will stabilize the fabric and give you really nice perfect circles!!!

Without the starch, you will probably notice that your jean fabric stretches and changes shape as you work with it.

TRACING Method:

I used a 6 1/2” plastic circle template to make the cardboard template seen below.

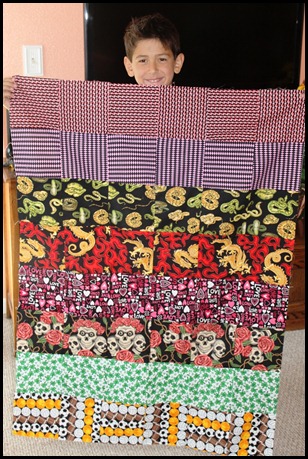

As you see, I can “typically” get eight circles from one leg but in in cases

where the legs are especially tapered you may only get six (i.e. smaller sized jeans).

You need a total of 16 circles so two legs (one pair of jeans) is usually sufficient.

OLFA CIRCLE CUTTING Method:

You will need one Olfa Rotary Circle Cutter (CMP-3). I

bought mine at my local fabric store.

It works just like a compass from math class.

It may seem a little intimidating at first, the directions on the package are not great. However, Olfa makes a video which does a terrific job explaining how to use it.

The video can be found here (video) . This is WELL

worth watching. It’s just a few minutes long. (Just scroll

down the page until you see the “circle cutter video”, click on

“English”.

They do a good job explaining how to set it up for measuring, etc.

*The cutter needs to be set at 3 1/4”. This is because you want a 6 1/2” finished circle.

It probably goes without saying but it is a lot more difficult to cut through denim using the circle cutter than it is to cut through quilting cotton.

You just need to go slower and be more patient because it does work great!

Here are my two best TIPS:

1. Before cutting the circles, spray starch the jeans. The more starch you use, the easier it will be to cut a perfect circle.

2. Wear gloves. I use gardening gloves. You have to apply a good amount of pressure to cut the circles and after a while this can be hard on your hands. With the gardening gloves, I could cut all day!

Of course another benefit of the circle cutter is that there is no need to mark the circles ahead of time!

Assembly:

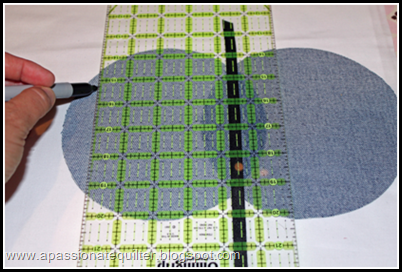

1. Once you have cut 16 circles, start by placing one

6 ½” circle Wrong Side UP on the table surface.

Align a ruler with the circle, 1” from edge.

2. Draw a line along the edge of the ruler.

This line will not be seen in the finished product so any

type of pen will work.

3. Place another circle under the one you just marked, Right Sides together!

4. Pin in place.

Sew along the marked line making sure to backstitch at BOTH ends of the seam.

Backstitching is very important throughout this process. Without it, your circles will start to fall apart when washed.

5. Lay flat the two circles and press open the flaps.

6. For this next step you will need a 6” or 6 ½” wide ruler.

Using the ruler, place the 4 ½” line directly over the seam (*the black ribbon in the picture is used to highlight the position of the seam, obviously, you won’t have a black ribbon!).

Once you align the seam with the 4 1/2” ruler mark, there should be a 1” space left over.

Place another ruler next to the 6” ruler. Use this ruler to make sure this space is exactly 1”.

Important:*If you do not have a 1” seam allowance , move the 6” ruler over until you have exactly 1”.

This can happen sometimes due to inconsistencies in cutting the circles and the space taken up by seam allowances, this will not affect how your finished pillow looks!

7. Remove the 1” ruler and draw a line.

8. With Right Sides Together, place another circle under the newly marked seam line.

Pin in place and sew. Remember to backstitch at both ends of the seam!!

9. Press the new seam open. You now have three joined circles, you need one more

for this row.

10. Starting with the most recently added circle, make a new seam line just as before…

Measure 4 ½” from the seam (black ribbon) to the edge of the circle. There should be a 1” space left over.

Place another ruler next to the 6” ruler. Use this ruler to measure the 1” seam allowance.

Again, if you do not have 1”, move the 6” ruler over until you have an exact 1” seam allowance.

11. Remove the 1” ruler and draw a new seam line.

12. Exactly as before, place a new circle under the marked one, Right Sides Together!

Pin and sew on the line, remembering to backstitch at both ends.

Press the flaps open. Each row should have four circles.

Do this three more times. You will need a total of four rows!

Get ready for Part 2, you will need:

-16 (4”) squares of batting

-16 (5”) fabric squares (either one solid color or a mixture, your choice!)

-four denim circle rows

-thread, I like to use a blue that matches most denims

![PA100001-537x402[1] PA100001-537x402[1]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEjUpF0F8aLj-G9Guc2bYSW0OlpTPDZTQWXmjDpmjLBV3RjqUhEl4nu8iQMss3rozuy7KqFuiNhClkniOcwAqnctTWGl7BEvrZdUqWOzRyJoDmA7r6MsUslJVntq86Jahtqg8npzvBfgA069/?imgmax=800)